Balls without cage

PM

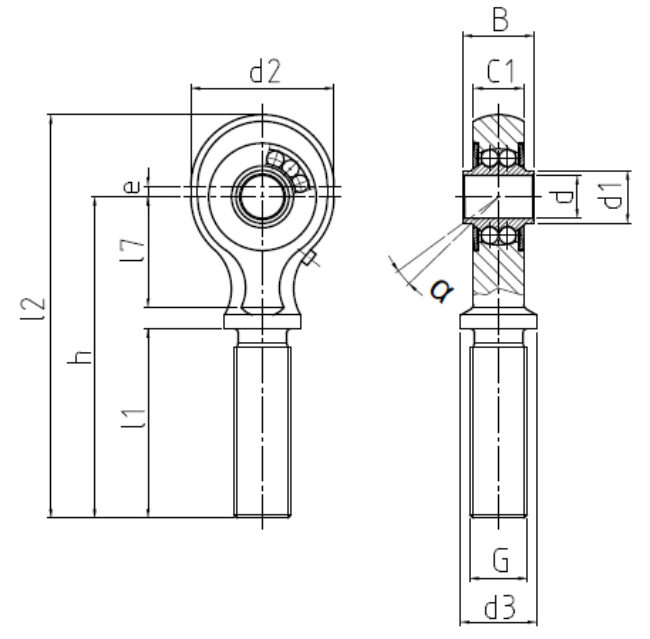

Rod ends with ball bearing, male thread, low maintenance, lubrication possible

Available Sizes

6 → 20

The Essential

DURBAL heavy-duty rod ends with integral self-aligning ball bearing, male thread

Right hand thread: PM_-00-501 and left hand thread: PM_-00-502

- Housing: 17Cr3 forged steel, case hardened bearing race, superfinished, surface galvanized, free of Cr VI

- Inner ring:100Cr6 ball bearing steel, hardened, superfinished

- Rolling element: 100Cr6 ball bearing steel, hardened, superfinished

- Maintenance: low maintenance, lubrication possible, aluminium-complex-soap-grease, approval according to USDA H1

- Grease nipple: DIN 3405 D1/A, further grease nipples.

- Temperature range: -45° C to +120° C

Special characteristics:

- For high speeds, wide swivelling angles or rotating movements,

- Low bearing friction,

- All rod end housings are made of forged steel, tempered, extremly high loads resistant and protected against corrosion by galvanisation.

- Low maintenance due to long-term lubrication with food-grade approval; the rod ends can be greased subsequently by means of a funnel-type lubrication nipple. Further special grease nipples available on request;

- Covering discs on both sides to prevent the penetration of coarse dirt particles inside the bearing.

- In standard length with designation PM _-00-501/-502. In shorter form with designation PM _-01-501/-502.

Available as a complete linkages (system) solution or separately with threaded links and hexagonal locking nuts. For shaft diameters from 6 mm to 20 mm.

| Type | d (mm) | G | d2 (mm) | l2 (mm) |

|---|---|---|---|---|

| PM 06 – 00 – 501 | 6 | M 10 x 1 | 24 | 77.5 |

| PM 06 – 00 – 502 | 6 | M 10 x 1 | 24 | 77.5 |

| PM 06 – 01 – 501 | 6 | M 10 x 1 | 24 | 54 |

| PM 06 – 01 – 502 | 6 | M 10 x 1 | 24 | 54 |

| PM 08 – 00 – 501 | 8 | M 12 x 1,5 | 30 | 89 |

| PM 08 – 00 – 502 | 8 | M 12 x 1,5 | 30 | 89 |

| PM 08 – 01 – 501 | 8 | M 12 x 1,5 | 30 | 65.5 |

| PM 08 – 01 – 502 | 8 | M 12 x 1,5 | 30 | 65.5 |

| PM 10 – 00 – 501 | 10 | M 14 x 1,5 | 36 | 102.5 |

| PM 10 – 00 – 502 | 10 | M 14 x 1,5 | 36 | 102.5 |

| PM 10 – 01 – 501 | 10 | M 14 x 1,5 | 36 | 79 |

| PM 10 – 01 – 502 | 10 | M 14 x 1,5 | 36 | 79 |

| PM 12 – 00 – 501 | 12 | M 16 x 1,5 | 40 | 113 |

| PM 12 – 00 – 502 | 12 | M 16 x 1,5 | 40 | 113 |

| PM 12 – 01 – 501 | 12 | M 16 x 1,5 | 40 | 88.5 |

| PM 12 – 01 – 502 | 12 | M 16 x 1,5 | 40 | 88.5 |

| PM 15 – 00 – 501 | 15 | M 20 x 1,5 | 42 | 124 |

| PM 15 – 00 – 502 | 15 | M 20 x 1,5 | 42 | 124 |

| PM 15 – 01 – 501 | 15 | M 20 x 1,5 | 42 | 97.5 |

| PM 15 – 01 – 502 | 15 | M 20 x 1,5 | 42 | 97.5 |

| PM 17 – 00 – 501 | 17 | M 20 x 1,5 | 48 | 132.5 |

| PM 17 – 00 – 502 | 17 | M 20 x 1,5 | 48 | 132.5 |

| PM 17 – 01 – 501 | 17 | M 20 x 1,5 | 48 | 106 |

| PM 17 – 01 – 502 | 17 | M 20 x 1,5 | 48 | 106 |

| PM 20 – 00 – 501 | 20 | M 24 x 1,5 | 56 | 148.5 |

| PM 20 – 00 – 502 | 20 | M 24 x 1,5 | 56 | 148.5 |

| PM 20 – 01 – 501 | 20 | M 24 x 1,5 | 56 | 121 |

| PM 20 – 01 – 502 | 20 | M 24 x 1,5 | 56 | 121 |

| Type | d (mm) | G | d2 (mm) | l2 (mm) |

You need some help with a 3D file?