E serie

EMA

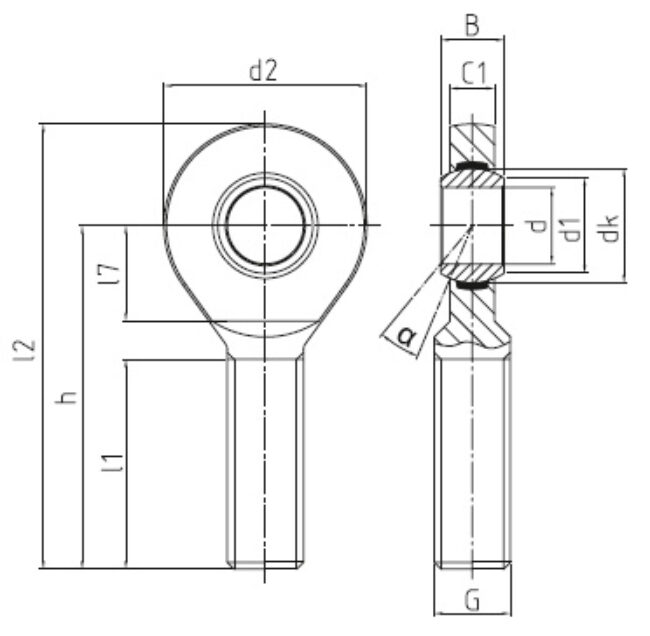

Rod ends in aluminium with DURBAL-Glide (PTFE), male thread, series E, DIN ISO 12240-4, maintenance free

Available Sizes

6 → 25

The Essential

DURBAL heavy-duty rod ends in aluminium with integral spherical-plain bearing, series E, male thread, according to DIN ISO 12240-4

Right hand thread: EMA_-60-501 and left hand thread: EMA_-60-502

- Housing: EN AW-7075 high-strength aluminum, surface anodized silver, several colour variants available additionally on request

- Race DURBAL-Glide: Polyamid-PTFE-fibreglass-Compound

- Joint ball: AISI 440b stainless steel, hardened, ground, polished

- Maintenance: maintenance-free

- Tolerances: see on this page

- Highlights: see on this page

- Temperature range: -30° C to +60° C

Special characteristics:

- Extreme low weight compared to other rod ends made of steel; for example EMA 12-60-501 ALU-type, weight: 0.028 kg; EM 12-60-501 stainless steel-type, weight: 0.067 kg

- The aluminium rod ends are insulated, in consequence do not conduct current and therefore ideal for outdoor applications

- DURBAL-Glide (race) made of polyamide-PTFE-glass fibre compound, maintenance-free, encapsulates penetrating foreign particles. This fact and the greater overlay thickness compared to other sliding materials assure a longer durability.

- Joint balls are made of stainless steel, hardened, ground, polished

- All housings are made of high-strength aluminium with a very good corrosion resistance, an extremely hard and scratch-resistant surface that is standard anodized silver; several colour variants available additionally on request. Furthermore all of them show a high mechanical load capacity.

- No clearance: radial clearance 0 – 10 µm;

- Suitable for use with impact loads;

- For use with small swivelling movements and at low speeds.

Installation instructions: using rod ends made of aluminium it is to ensure that during assembly the thread will not be damaged. Therefore these rod ends have to be countered with nuts according to DIN 934 only. We recommend to use a Threadlocker such as „LOCTITE 243“

Available as a complete linkages (system) solution or separately hexagonal locking nuts. For shaft diameters from 6 mm to 25 mm.

| Type | d (mm) | G | d2 (mm) | l2 (mm) |

|---|---|---|---|---|

| EMA 06 – 60 – 501 | 6 | M 6 | 20 | 46 |

| EMA 06 – 60 – 502 | 6 | M 6 | 20 | 46 |

| EMA 08 – 60 – 501 | 8 | M 8 | 23 | 53.5 |

| EMA 08 – 60 – 502 | 8 | M 8 | 23 | 53.5 |

| EMA 10 – 60 – 501 | 10 | M 10 | 28 | 62 |

| EMA 10 – 60 – 502 | 10 | M 10 | 28 | 62 |

| EMA 12 – 60 – 501 | 12 | M 12 | 32 | 70 |

| EMA 12 – 60 – 502 | 12 | M 12 | 32 | 70 |

| EMA 15 – 60 – 501 | 15 | M 14 | 38 | 82 |

| EMA 15 – 60 – 502 | 15 | M 14 | 38 | 82 |

| EMA 17 – 60 – 501 | 17 | M 16 | 44 | 91 |

| EMA 17 – 60 – 502 | 17 | M 16 | 44 | 91 |

| EMA 20 – 60 – 501 | 20 | M 20 x 1,5 | 51 | 103.5 |

| EMA 20 – 60 – 502 | 20 | M 20 x 1,5 | 51 | 103.5 |

| EMA 25 – 60 – 501 | 25 | M 24 x 2 | 62 | 125 |

| EMA 25 – 60 – 502 | 25 | M 24 x 2 | 62 | 125 |

| Type | d (mm) | G | d2 (mm) | l2 (mm) |

You need some help with a 3D file?