BRM Niro

-

The Essential

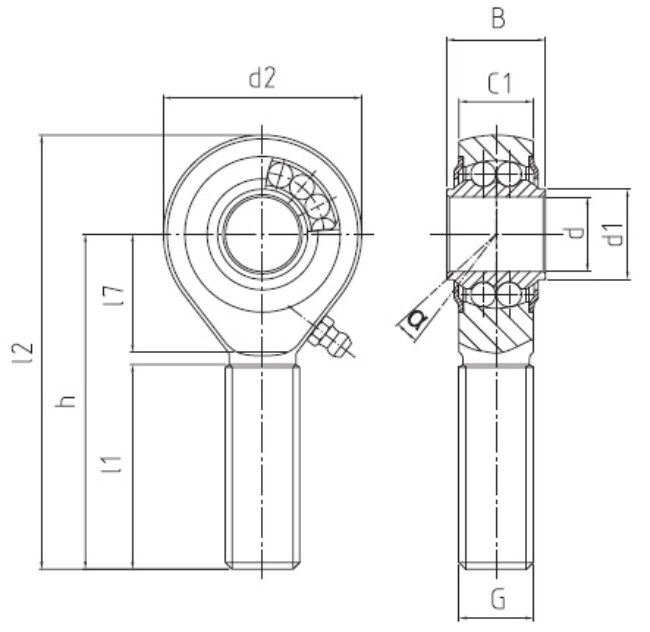

DURBAL heavy-duty rod ends in stainless steel, with integral self-aligning ball bearing, series K, male thread, according to ISO 12240-4

Right hand thread: BRM_-60-501 and left hand thread: BRM_-60-502- Housing: AISI 304 stainless steel, forged, hardened, bearing race superfinished, size 18, 22, 25, 30 can be made as turning part, surface electropolished

- Inner ring: AISI 440b stainless steel, hardened, superfinished

- Rolling element: AISI 440c stainless steel, hardened, super

- Maintenance: low maintenance, lubrication possible, aluminium-complex-soap-grease, approval according to USDA H1

- Grease nipple in stainless steel: DIN 3405 D1/A (until size 10) / DIN 71 412 H1 (from size 12), further grease nipples.

- Temperature range: -45° C to +120° C

Special characteristics:

- For high speeds, wide swivelling angles or rotating movements,

- Low bearing friction,

- Mainly all rod end housings are made of forged stainless steel, extremly high loads resistant and surface electropolished which ensures you a very high corrosion resistance.

- Low maintenance due to long-term lubrication with food-grade approval; the rod ends may be subsequently lubricated by means of a funnel or conical grease nipple. Further special grease nipples available on request;

- Covering discs in stainless steel on both sides to prevent the penetration of coarse dirt particles inside the bearing.

Assembly instruction only for heavy-duty rod ends in stainless steel with integral self-aligning ball bearing with male-thread.

DURBAL Premium Line stainless steel heavy-duty rod ends are all hardened to ensure a long life time even under higher loads.

Therefore torques have to be used according to the table**. Moreover, these heavy-duty rod ends should only be used in areas, where no transverse forces act on the thread.Available as a complete linkage (system) solution or separately with stainless steel hexagonal locking nuts. For shaft diameters from 8 mm to 30 mm.

Type d (mm) G d2 (mm) l2 (mm) BRM 08 – 60 – 501 8 M 8 24 54 BRM 08 – 60 – 502 8 M 8 24 54 BRM 10 – 60 – 501 10 M 10 28 62 BRM 10 – 60 – 502 10 M 10 28 62 BRM 12 – 60 – 501 12 M 12 32 70 BRM 12 – 60 – 502 12 M 12 32 70 BRM 16 – 60 – 501 16 M 16 42 87 BRM 16 – 60 – 502 16 M 16 42 87 BRM 18 – 60 – 501 18 M 18 x 1,5 46 95 BRM 18 – 60 – 502 18 M 18 x 1,5 46 95 BRM 20 – 60 – 501 20 M 20 x 1,5 50 103 BRM 20 – 60 – 502 20 M 20 x 1,5 50 103 BRM 22 – 60 – 501 22 M 22 x 1,5 54 111 BRM 22 – 60 – 502 22 M 22 x 1,5 54 111 BRM 25 – 60 – 501 25 M 24 x 2 64 126 BRM 25 – 60 – 502 25 M 24 x 2 64 126 BRM 30 – 60 – 501 30 M 30 x 2 70 145 BRM 30 – 60 – 502 30 M 30 x 2 70 145 Type d (mm) G d2 (mm) l2 (mm)